If you want something that’s tailor-made to your requirements, our task at KIAN is to help you achieve what you’re looking for. Here’s how we did it for one client.

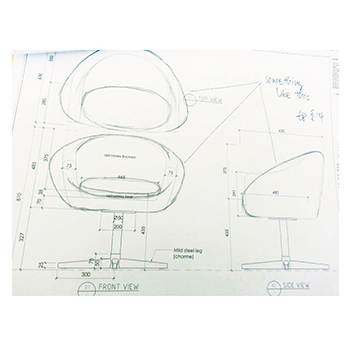

Our client told us what was needed and what they had in mind. We explored some ideas together until a feasible design was decided on that met their requirements.

2. MOCK-UPS

2. MOCK-UPS

The next step was to create a few prototypes or mock-ups to give an idea of what the final product would look like. Detailing and fine-tuning (such as choice of colours, fabrics, textures, wood stains and metal finishings) were done at this stage to ensure that the model had every feature that was agreed upon.

3. IMPROVEMENT

3. IMPROVEMENT

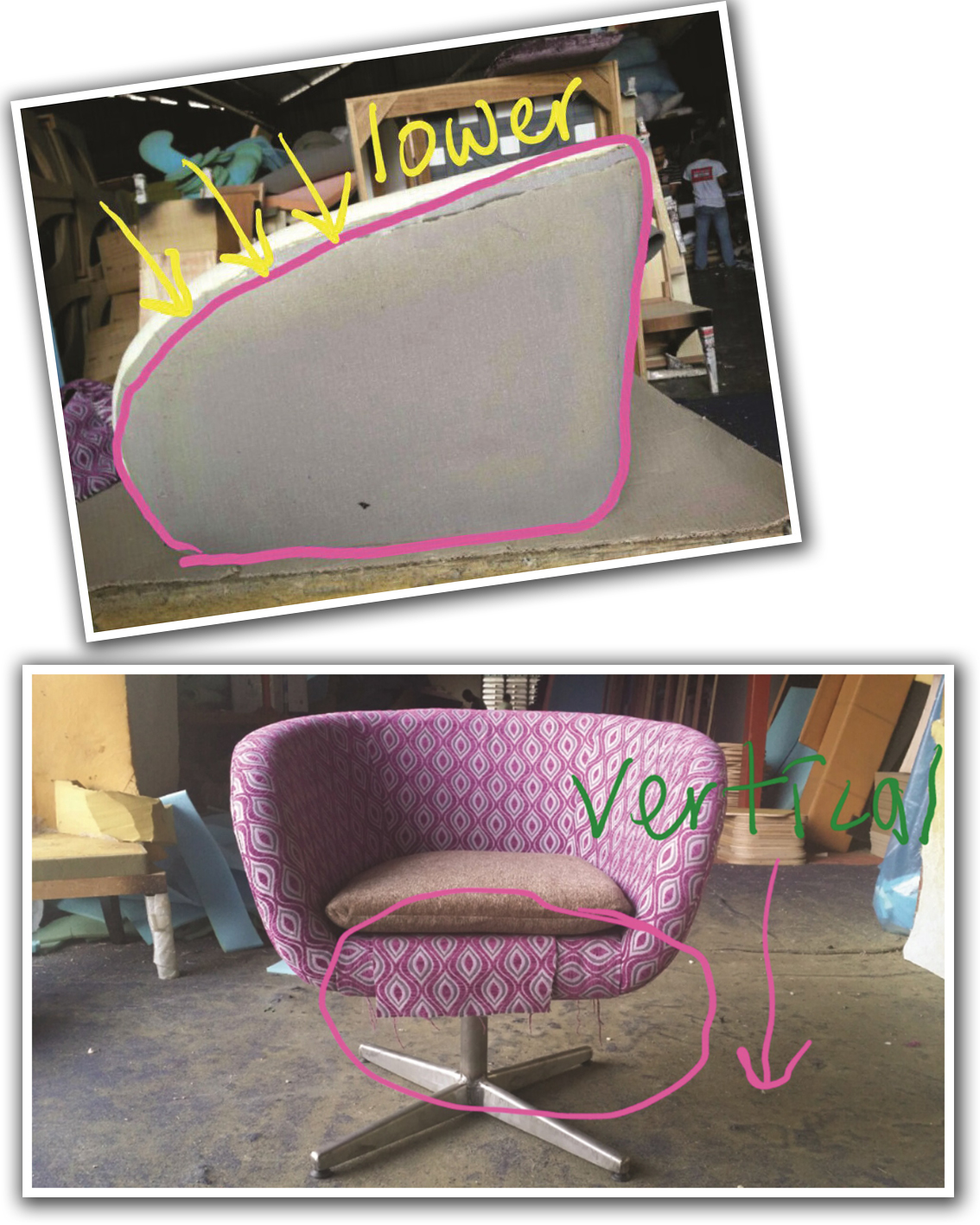

Then our manufacturing expertise took over. We adhered to the original design but drew on our knowledge and technical experience to improve on crucial aspects such as ergonomics, stability and the ability of the item to maintain its shape over time.

4. PRODUCTION

The item took shape and was fully produced. Not only did we keep to the specifications agreed upon, the piece was also made better.

5. COST EFFICIENCY

The final product! We called on our R&D knowledge and technical skills to value-engineer the creation of this chair. It’s better quality at less the expense.